Metal Sheathed Inorganic Mineral Insulated Cable

Metal Sheathed Inorganic Mineral Insulated Cable

Application

Metal sheathed inorganic mineral insulated fire-resistant flexible cable is a new product which is developed and designed independently by ANHUI HUAYU CABLE GROUP CO., LTD. during about two years. It contains two types: RTTZ、 RTTZE coppe core corrugated copper sheathed inorganic mineral insulated fire-resistant fexible cable and RTGZ、 RTGZE copper core corrugatedstainless steel sheathed inorganic mineral insulated fire-resistant fexible cable. They can be substitutes for BTTZ copper core coppeisheathed mineral insulated cable with almost same manufacturing length as ordimary cable. It has many advantages such as large sections.multi-core, fexibility, large current capacity, fewer joints and east installation.

Type and Description

| Type | Description |

| RTTZ(YTTW) | Copper core corrugated copper sheathed inorganic mineral insulated cable |

| RTTZE | Copper core corrgated copper sheathed inorganic mineral insulated low-smoke and halogen-freepolyolefin outer sheathed cable |

| RTGZ(YTGW) | Copper core corrugated stainless steel sheathed inorganic mineral insulated cable |

| RTGZE(YTGWE) | Copper core corugated stainless steel sheathed inorganic mineralinsulated low-smoke and halogen-free polyolefn outer sheathed cable |

Specification

| Type | Rated Voltage | Cores No. | Nominal Cross Section mm2 |

| RTTZ RTTZE RTGZ RTGZE |

450/750v 0.6/1kv |

1 | 1~630 |

| 2,3 | 1~300 | ||

| 4,5 | 1~240 | ||

| 3+1,4+1 | 2.5~240 | ||

| 7~37 | 1~2.5 |

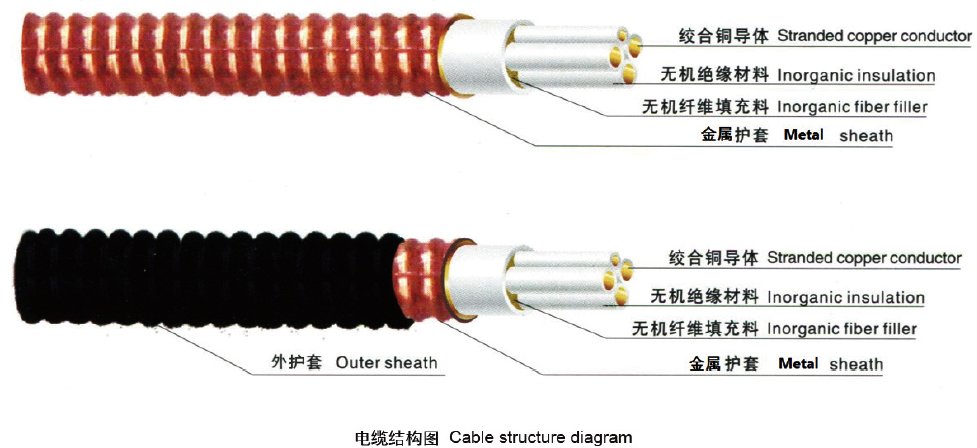

Construction of inorganic mineral insulated cable

1) Conductor: stranded copper wires, excellent flexibility.

2) Insulation: high-temperature and incombustible inorganic mineral.

3) Copper sheath: copper material with good flexibility which can be used as PE wire.Steel sheath: stainless steel, non-magnetic material with good fexibility and better property of corrosion resistance.

4) Outer sheath: except copper sheath, low-smoke and halogen-free polyolefin with good property of corrosion resistanceshall be as outer sheath which is used at chemical industry locations.

Fire-resistant property for inorganic mineral insulated cable

1. According to GB12666.6

With 750V between phases, phase and outer sheath, there shall be no damage to the insulation of type A cable while bumning in famewith 950 ℃~1000 ℃ for 90min.

With 750v between phases, phase and outer sheath, there shall be no damage to the insulation of type B cable while buming in fiamewith 750℃~800℃ for 90min.

2. As per BS6378, the fire resistant property by testing of the fireproof fexible cable should comply with following requirements.GGrade A should withstand 650℃ for 3h:

Grade B should withstand 750℃ for 3h:

Grade C should withstand 950℃ for 3h:

Grade S should withstand 950℃ for 20min.

Features for mineral insulated cable

1. Perfect fire-resistant propertyIt is complying with not only 950′ 90min for grade A stipulated in national standard GB12666.6, but also 650′ 3h for grade A750’℃ 3h for grade B and 950’c 3h for grade C stipulated in B56387-1994. water spray and mechanical erash will be bearable for thecable while on fre.

2. Large continuous cable length

Both sigle core and mulli-core cable can be long enough for power supply length. The medium-sized cables can be as long as 1000mwhile 2000m for small-sized cables.

3. Large cross-section

Single-core cable can be as large as 630mm’ while 240 mm’ for multi-core cable.

4. Flexibility

Cables can be woumd round drums with bending radius of no more than 20D (D: outer diameter for cable)

5. No sioke, no toxic gas and halogen-free while burning

For inorgamie material insulation, no toxic gas and leftover after buming for cable. Without secondary pollution and no self-ignition.

it deserves to be called environmental product.

6. Large overload capability

The cable acqures large curent-caurying capacily as well as overload capability, According to winmg requrements, the temperaturefor cable sheath could be as high as 105′ while not being touched and not being together with combustive constnctional materials. Thelong-term working temperature for fire-resistant cable is up to 250℃’under overloading.

7. Resistauce to coloslon

The flexible fire-resistant cable is produced with copper sheath and stainless steel sheath which has good resistance to corrosion. It isdiferent from organic insulated fre-resistant cable which has to be laid in plastic or iron tubes prone to be brittle after aging and msty.

8. No electromagnetic interference (EM)

There are no imnterfere between the cable and information or control cable which are laid together in the same shalt for its metal sheathacting a screen

9. High safety

The fire-resistant cable can still work on fame so as to launch the fire-extinguishing equipment to reduce cost. The copper sheath withcontinuous length as long as cable length, is the good conductor and best grounded PE wire which can improve sensitivity and reliability

for grounded protection.

10. Long service life

The inorganic insulated materials with resistance to high temperatue and aging enioy long service life of many times greater than thalof organic insulated cable. As usual, it will be used as long as the building and much longer for stainless steel sheathed cable

11. Easy installation

Including accessories, transportation and installation for fire-resistant flexible cable is almost as easy as ordinary cable

12. Economical

Produced by advanced techmology and imstalled easily, the overall cost for fexible fire-resistant cable will be reduced comparedmineral insulated cable under the same conditions.

13. Allowable bending radius for the cable

| Outer diameter(mm) | D≤12 | 12<D≤20 | 20<D≤50 |

| Allowable bending radius for the cable (mm) | 6D | 10D | 15D |

Electrical performances for mineral insulated cable

1. Rated voltage: up to and including 0.6/1kV.

2. Rated curent: 25A-1800A for single core, 16A-500A for multi-core.

3. Insulation resistance:>100M Ω/km.

4. Power frequency voltage: with 2500V behween phases, phase and metal sheath for cables with rated voltage of 450/750V and 3500\for cables with voltage of 0.6/lkV, those cables shall withstand the voltages for 15min without breakdown.

Selection of inorganic mineral insulated cable

1. Selection ofsingle core cable and multi-core cableIf the current-carrying capacity is higher than 500A, the single core cable will be used for its higher curent-canrying capacitycompared with mulfi-core cable. And two single core cables can be laid in parallel in order to meet the capacity requrement. However.

the multi-core cable has even impedance for balanced eleetric parameter of each core.

2. Cuent-caiiy capacity of cableAccording to GB/Tl6895.15 ( [EC60287 ), The capacity of the cable is calculated based on ambient temperature of 40′ andworking temperature of 90′, Depending on the situations, in order to increase the capacity, requirement of tenminal voltage drop andsecurity of installation shall be safisfed,

3. Anti-corrosive

If being imstalled at chemical places with moisture and corrosion, RIT2 or RTGZ cable shall used for wonderfiul anti-corosiveproperty of RTTZE cable and better for RTGZE cable.4.Cable grounding

The copper sheath of RTTZ cable with cross-section complying with requirements stipulated is best PE wire. So, the four-core cablecould be used as five-core one, One end of multi-core cable shall be grounded and both ends for single core cable. If one end groundedthe other end must be isolated by electric insulation and the copper sheath may have several grounded points.It will reduce the cost to use RTGZ cable if one single cable used with or without pE wire. kTG;Z cable is the new substilute for lowsmoke halogen-free steel tape armored cable. And it shall be grounded with one end.

5. Branch box and pre-distribution cable

In branch distribution system, Branch box and pre-distribution cable shall be used for no sections to main line so as to reducebreakdown points. The cable can be directly laid by bracket without cable tray.

6. Accessories of cable

As usual, the fire-resistant fiexible cable can be used without any accessories, There wil be termimnals like ordinary cables. if neededour company will provide terminals and connectors.

7. Calculation of designed length ofeableThe fexibility of the cable enables it to remove damages from the natural stress and electromotive power without S or U type jointsThere shall be additional length of 1.$-2 meters for cable bending naturally into S or U during installation.

8. InstallationThe cable can be laid directly without cable tray. The multi-core cable can penetrate the iron pipe pre-bured in floor slabs with irorfastening device. The single core cable is exactly prohibited to be wrapped in iron piece or other high magnetic materials. Some singlcore cables can be wrapped or in pipe together.

Product Image

RELATED PRODUCTS

GET IN TOUCH

We look forward to serving you! Our team will get back to you promptly.

Power Cable

Power Cable General Power Cable

General Power Cable XLPE insulated power cable for rated voltage up to and including 35kV

XLPE insulated power cable for rated voltage up to and including 35kV XLPE insulated anti-termite and anti-rat environmental power cable for rated voltage up to & including 35kV

XLPE insulated anti-termite and anti-rat environmental power cable for rated voltage up to & including 35kV XLPE insulated waterproof power cable for rated voltage up to and including 35KV

XLPE insulated waterproof power cable for rated voltage up to and including 35KV Silicon rubber insulated power cable

Silicon rubber insulated power cable Fluoroplastics insulated heat resistant power cable

Fluoroplastics insulated heat resistant power cable NBR Flexible Power Cable

NBR Flexible Power Cable Power cable with concentric conductor

Power cable with concentric conductor Special cable for frequency converter

Special cable for frequency converter Metal shielded power cable

Metal shielded power cable Oxygen barrier and high flame retardant power cable

Oxygen barrier and high flame retardant power cable EPR insulated power cable for rated voltage up to and including 35kV

EPR insulated power cable for rated voltage up to and including 35kV Plastic insulated and sheathed branch cable of rated voltage up to and including 0.6/1kV

Plastic insulated and sheathed branch cable of rated voltage up to and including 0.6/1kV 0.6/1kV PVC insulated power cable

0.6/1kV PVC insulated power cable 0.6/1kV polyolefin insulated power cable

0.6/1kV polyolefin insulated power cable 0.6/1kV flame retardant B1 class power cable

0.6/1kV flame retardant B1 class power cable 0.6/1kV flame retardant B2 class power cable

0.6/1kV flame retardant B2 class power cable Aluminium Alloy Power Cable

Aluminium Alloy Power Cable Special Explosion Proof Cable

Special Explosion Proof Cable 8.7/15KV And Below Medium Voltage Special Explosion-Proof Cable

8.7/15KV And Below Medium Voltage Special Explosion-Proof Cable 450/750V and below Special Explosion-Proof Control cable

450/750V and below Special Explosion-Proof Control cable 300/500V Special Explosion-Proof Computer Cable

300/500V Special Explosion-Proof Computer Cable Mineral Insulated Fire-proof Cable

Mineral Insulated Fire-proof Cable Metal sheathed inorganic mineral insulated cable

Metal sheathed inorganic mineral insulated cable Copper core mineral insulated flexible fire proof cable for wiring rated voltage upto and including 0.6/1kV

Copper core mineral insulated flexible fire proof cable for wiring rated voltage upto and including 0.6/1kV Industrial Cable & Civil Cable

Industrial Cable & Civil Cable Industrial Control Cable

Industrial Control Cable XLPE insulated and sheathed control cable

XLPE insulated and sheathed control cable PVC insulated and sheathed control cable

PVC insulated and sheathed control cable Polyolefin insulated and sheathed control cable

Polyolefin insulated and sheathed control cable NBR insulated and sheathed flexible control cable

NBR insulated and sheathed flexible control cable Thermoplastic elastomer insulated and sheathed flexible control cable

Thermoplastic elastomer insulated and sheathed flexible control cable Fluoroplastic insulated high temperature resistant control cable

Fluoroplastic insulated high temperature resistant control cable 450/750V flame retardant B1 level control cable

450/750V flame retardant B1 level control cable Thermocouple Compensation Cable

Thermocouple Compensation Cable Rubber Sheathed Cable for General Purpose

Rubber Sheathed Cable for General Purpose Rubber insulated flexible cord and cable

Rubber insulated flexible cord and cable Welding Cable

Welding Cable Flexible cables & cords for electric motors leads

Flexible cables & cords for electric motors leads 125℃ & 150℃ Flexible Cable(Wire) for Motor Winding Connection

125℃ & 150℃ Flexible Cable(Wire) for Motor Winding Connection Movable Flat Cable

Movable Flat Cable Silicon rubber Insulated flat cable

Silicon rubber Insulated flat cable EPR Insulated flat cable

EPR Insulated flat cable NBR insulated flat cable

NBR insulated flat cable Heat-resistent Fire-proof Cable (Fire Protection Type)

Heat-resistent Fire-proof Cable (Fire Protection Type) Fireproof cable for high temperature uses

Fireproof cable for high temperature uses Automatic Control Temperature Heating Cable

Automatic Control Temperature Heating Cable Automatic-control-temperature Heating Cable

Automatic-control-temperature Heating Cable Low temperature, Middle temperature, High temperature series

Low temperature, Middle temperature, High temperature series The series of excessively-long cable

The series of excessively-long cable Maintaining temperature for duct

Maintaining temperature for duct The Comprehensive Application of Automatically-Restricted-Temperature Electric-Heating Belt into the Household Electric Equipment

The Comprehensive Application of Automatically-Restricted-Temperature Electric-Heating Belt into the Household Electric Equipment The Component of the explosion-proof heating belt andaccessories of installation

The Component of the explosion-proof heating belt andaccessories of installation Installation Cable Residential Wire

Installation Cable Residential Wire PVC insulated cable (wire)

PVC insulated cable (wire) Low smoke halogen free flame retardant and environmental installation wire

Low smoke halogen free flame retardant and environmental installation wire Cable for Railway Vehicle & Metro

Cable for Railway Vehicle & Metro EPR rubber insulated cable for railway vehicles & metro

EPR rubber insulated cable for railway vehicles & metro XLPO insulated cable for railway vehicies & metro

XLPO insulated cable for railway vehicies & metro NR+SBR insulated cable for railway vehicles & metro

NR+SBR insulated cable for railway vehicles & metro CSP rubber insulated cable for raiiway vehicles

CSP rubber insulated cable for raiiway vehicles Communication Cable

Communication Cable Instrumentation Cable

Instrumentation Cable PE or XLPE insulated computer cable

PE or XLPE insulated computer cable PVC insulated computer cable

PVC insulated computer cable Fluoroplastics insulated computer cable

Fluoroplastics insulated computer cable PAS/BS5308 Part1 Type 1&2

PAS/BS5308 Part1 Type 1&2 PAS/BS5308 Part2 Type 1&2

PAS/BS5308 Part2 Type 1&2 Fire Resistant Instrumention Cable

Fire Resistant Instrumention Cable Radio Frequency Cable

Radio Frequency Cable EIA RS485 RS232/RS422

EIA RS485 RS232/RS422 Bus Cable

Bus Cable LAN/ Network Cable

LAN/ Network Cable Fiber Optic Cable

Fiber Optic Cable Mining Cable

Mining Cable Flexible Coalcutter Cables for Rated Voltage up to and Including 1.9/3.3kV

Flexible Coalcutter Cables for Rated Voltage up to and Including 1.9/3.3kV Flexible Strengthened Coalcutter Cables With Monitoring Core and Screen for Rated Voltage of 0.66/1.14kV

Flexible Strengthened Coalcutter Cables With Monitoring Core and Screen for Rated Voltage of 0.66/1.14kV Flexible Coalcutter Cables With Metallic Screen For rated Voltage up to and Including 1.9/3.3kV

Flexible Coalcutter Cables With Metallic Screen For rated Voltage up to and Including 1.9/3.3kV Flexible Rubber-Sheathed Cables for Rated Voltage up to and Including 0.66/1.14kV

Flexible Rubber-Sheathed Cables for Rated Voltage up to and Including 0.66/1.14kV LSZH Flexible Rubber-Sheathed Cables for Rated Voltage up to and including 0.66/1.14kV

LSZH Flexible Rubber-Sheathed Cables for Rated Voltage up to and including 0.66/1.14kV Drill Cables with Rated Voltage of 0.3/0.5kV for Mining Purpose

Drill Cables with Rated Voltage of 0.3/0.5kV for Mining Purpose Flexible Rubber-Sheathed Light-Duty Cables for Mining Purpose

Flexible Rubber-Sheathed Light-Duty Cables for Mining Purpose PVC Insulated Flame Retardant Mining Power Cable

PVC Insulated Flame Retardant Mining Power Cable XLPE Insulated Mining Power Cable

XLPE Insulated Mining Power Cable Flame-Retardant Mining Control Cable

Flame-Retardant Mining Control Cable Reeling Cable &Trailing Cable

Reeling Cable &Trailing Cable Low voltage reeling cable

Low voltage reeling cable Spreader rolling cable

Spreader rolling cable Spreader basket cable

Spreader basket cable Shipboard Cable & Marine Engineering

Shipboard Cable & Marine Engineering Shipyard Cable & Marine Cable & Offshore Cable

Shipyard Cable & Marine Cable & Offshore Cable EPR insulated shipboard power cable for rated voltage from 3.6/6 to 18/30kV

EPR insulated shipboard power cable for rated voltage from 3.6/6 to 18/30kV XLPE insulated shipboard power cable for rated voltage from 3.6/6 to 18/30kV

XLPE insulated shipboard power cable for rated voltage from 3.6/6 to 18/30kV EPR insulated shipboard power cable rated voltage up to and including 0.6/1kV

EPR insulated shipboard power cable rated voltage up to and including 0.6/1kV EPR insulated Fire-Resisting shipboard power cable rated voltage up to and including 0.6/1kV

EPR insulated Fire-Resisting shipboard power cable rated voltage up to and including 0.6/1kV XLPE insulated shipboard power cable for rated voltage up to and including 0.6/1kV

XLPE insulated shipboard power cable for rated voltage up to and including 0.6/1kV Marine Control Cable

Marine Control Cable XLPE insulated shipboard Control cable rated voltage up to and including 250V

XLPE insulated shipboard Control cable rated voltage up to and including 250V XLPE insulated Fire-Resisting shipboard Control cable rated voltage up to and including 250V

XLPE insulated Fire-Resisting shipboard Control cable rated voltage up to and including 250V EPR insulated Fire-Resisting shipboard Control cable rated votage up to and including 250V

EPR insulated Fire-Resisting shipboard Control cable rated votage up to and including 250V Marine Instrumentation cable & Communication cable

Marine Instrumentation cable & Communication cable XLPE insulated Fire-Resisting shipboard telecommunication cable for rated voltage up to and including 250V

XLPE insulated Fire-Resisting shipboard telecommunication cable for rated voltage up to and including 250V EPR insulated shipboard telecommunication cable for rated voltage up to and including 250V

EPR insulated shipboard telecommunication cable for rated voltage up to and including 250V EPR insulated Fire-Resisting shipboard telecommunication cable for rated voltage up to and including 250V

EPR insulated Fire-Resisting shipboard telecommunication cable for rated voltage up to and including 250V Naval Ship Cable

Naval Ship Cable Naval Ship Power Cable

Naval Ship Power Cable XLPE insulated naval ship power cable for rated voltage up to and including 0.6/1kV

XLPE insulated naval ship power cable for rated voltage up to and including 0.6/1kV EPR insulated naval ship power cable for rated voltage up to and including 0.6/1kV

EPR insulated naval ship power cable for rated voltage up to and including 0.6/1kV Naval Ship Control Cable

Naval Ship Control Cable EPR insulated naval ship control cable for rated voltage up to and including 600V

EPR insulated naval ship control cable for rated voltage up to and including 600V Naval Ship Instrumentation cable & Communication cable

Naval Ship Instrumentation cable & Communication cable XLPE insulated naval ship telecommunication cable for rated Voltage up to and including 300V

XLPE insulated naval ship telecommunication cable for rated Voltage up to and including 300V Low-smoke halogen-free flame-retardant light thin-walled telecommunication cable for naval ships

Low-smoke halogen-free flame-retardant light thin-walled telecommunication cable for naval ships Watertight Cable for Naval Ship

Watertight Cable for Naval Ship Watertight Power Cable

Watertight Power Cable XLPE insulated naval ship water-tightness power cable for rated voltage up and including 0.6/1kV

XLPE insulated naval ship water-tightness power cable for rated voltage up and including 0.6/1kV Watertight Control Cable

Watertight Control Cable XLPE insulated naval ship water-tightness control cable for rated voltage up to and including 600V

XLPE insulated naval ship water-tightness control cable for rated voltage up to and including 600V XLPE insulated naval ship water-tightness fire-resistance control cable for rated voltage up to and including 600V

XLPE insulated naval ship water-tightness fire-resistance control cable for rated voltage up to and including 600V EPR insulated naval ship water-tightness control cable for rated voltage up to and including 600V

EPR insulated naval ship water-tightness control cable for rated voltage up to and including 600V EPR insulated naval ship water-tightness fire-resistance control cable for rated voltage up to and including 600V

EPR insulated naval ship water-tightness fire-resistance control cable for rated voltage up to and including 600V XLPE insulated naval ship water-tightness fire-resistant telecommunication cable for rated voltage up to and including 300V

XLPE insulated naval ship water-tightness fire-resistant telecommunication cable for rated voltage up to and including 300V EPR insulated naval ship water-tightness telecommunication cable for rated voltage up to and including 300V

EPR insulated naval ship water-tightness telecommunication cable for rated voltage up to and including 300V EPR insulated naval ship water-tightness fire-resistant telecommunication cable for rated voltage and including 300V

EPR insulated naval ship water-tightness fire-resistant telecommunication cable for rated voltage and including 300V Low smoke shore connection cable for naval ships

Low smoke shore connection cable for naval ships Rubber cable for underwater sound transducer

Rubber cable for underwater sound transducer Aramid fiber strength signal cable for naval ships

Aramid fiber strength signal cable for naval ships Low smoke digital communication LAN cable

Low smoke digital communication LAN cable LV Power Cable for Oil Platform

LV Power Cable for Oil Platform Power cable for offshore oil platform with rated voltage up to and including 0.6/1 kV

Power cable for offshore oil platform with rated voltage up to and including 0.6/1 kV Fire-Resisting power cable for offshore oil platform with rated voltage up to and including 0.6/1kV

Fire-Resisting power cable for offshore oil platform with rated voltage up to and including 0.6/1kV Telecommunication cable for offshore oil platform with rated voltage up to and including 150/250V

Telecommunication cable for offshore oil platform with rated voltage up to and including 150/250V EPR insulated power cable for offshore oil platform with rated voltage from 3.6/6 to 18/30kV

EPR insulated power cable for offshore oil platform with rated voltage from 3.6/6 to 18/30kV New Energy Cable

New Energy Cable Wind Power Generation Cable

Wind Power Generation Cable Wind Power mobile cold-proof anti-reversing Control cable

Wind Power mobile cold-proof anti-reversing Control cable Solar/Photovoltaic Cable

Solar/Photovoltaic Cable Solar Cable TUV 2PFG 1169

Solar Cable TUV 2PFG 1169 EV Charging Cable EN50620

EV Charging Cable EN50620 EV Cable H05BZ5-F & H07BZ5-F

EV Cable H05BZ5-F & H07BZ5-F Special Cable

Special Cable Special Industrial Cable

Special Industrial Cable XT Series Phase-Stable Low-Loss Coaxial Cable

XT Series Phase-Stable Low-Loss Coaxial Cable SFF Series Solid PTFE Insulated RF Coaxial Cable

SFF Series Solid PTFE Insulated RF Coaxial Cable SYV Series Solid PE Insulated RF Coaxial Cable

SYV Series Solid PE Insulated RF Coaxial Cable Field-Use XTFUP-1004x2x24A Type Special Ethernet Cable

Field-Use XTFUP-1004x2x24A Type Special Ethernet Cable Field-Use DVl Video Transmission Cable

Field-Use DVl Video Transmission Cable Field-Use VGA Video Transmission Cable

Field-Use VGA Video Transmission Cable Field-Use AGTRQ Series Special Flexible Wire

Field-Use AGTRQ Series Special Flexible Wire Field-Use XTRT Series Special Flexible Power Cable

Field-Use XTRT Series Special Flexible Power Cable Field-Use XERJ Series Abrasion-Resistant Flexible Power Cable

Field-Use XERJ Series Abrasion-Resistant Flexible Power Cable Metal Braid Series A: XTP Series EMl Shielding Sleeve

Metal Braid Series A: XTP Series EMl Shielding Sleeve Metal Braid Series B: XTP Series Grounding Cable

Metal Braid Series B: XTP Series Grounding Cable Field-Use Computer Cable

Field-Use Computer Cable Field-Use Special Control Cable

Field-Use Special Control Cable Aeropace/Aviation Cable

Aeropace/Aviation Cable XTA1 Series High-Performance Transmission wire for Aerospace

XTA1 Series High-Performance Transmission wire for Aerospace XTA2 Series High-Performance Transmission wire for aviation

XTA2 Series High-Performance Transmission wire for aviation XTA3 Series High-Performance Transmission wire for aviation

XTA3 Series High-Performance Transmission wire for aviation XTAX Series High-Performance Ultra-Flexible Transmission wire for aviation

XTAX Series High-Performance Ultra-Flexible Transmission wire for aviation XTE Series High-Temperature Resistant Wire for aviation

XTE Series High-Temperature Resistant Wire for aviation XTER Series High-Temperature Resistant Wire for aviation

XTER Series High-Temperature Resistant Wire for aviation XTEX Series High-Temperature Resistant Ultra-Flexible Wire for aviation

XTEX Series High-Temperature Resistant Ultra-Flexible Wire for aviation AFR-250 Series PTFE Film-Wrapped Insulated Installation Wire for aviation

AFR-250 Series PTFE Film-Wrapped Insulated Installation Wire for aviation AF Series Fluorinated Ethylene Propylene (FEP) Insulated Wire for aviation

AF Series Fluorinated Ethylene Propylene (FEP) Insulated Wire for aviation AF Series Soluble Polytetrafluoroethylene (PFA) Insulated Wire for aviation

AF Series Soluble Polytetrafluoroethylene (PFA) Insulated Wire for aviation XTCMC Large-Cross-Section Flexible Wire for aviation

XTCMC Large-Cross-Section Flexible Wire for aviation C55 Series Aerospace-Grade Crosslinked Ethylene-Tetrafluoroethylene Copolymer (XETFE) single-Layer Insulated Wire

C55 Series Aerospace-Grade Crosslinked Ethylene-Tetrafluoroethylene Copolymer (XETFE) single-Layer Insulated Wire XETFE-Insulated 1553B Data Bus Cable for aerospace

XETFE-Insulated 1553B Data Bus Cable for aerospace Model C772451664 Aerospace-Grade 1553B Data Bus Cable

Model C772451664 Aerospace-Grade 1553B Data Bus Cable Aviation-Grade 100Ω Special Category 5e Cable

Aviation-Grade 100Ω Special Category 5e Cable Model THSFPF 1x4x24A High-Temperature Resistant 100Ω Special Transmission Cable for aerospace

Model THSFPF 1x4x24A High-Temperature Resistant 100Ω Special Transmission Cable for aerospace Model THWFPF-110 1x4x24A 1394b Data Bus Cable for aerospace

Model THWFPF-110 1x4x24A 1394b Data Bus Cable for aerospace Model XT2490 &XT2539 LVDS Transmission Cable for aerospace

Model XT2490 &XT2539 LVDS Transmission Cable for aerospace