0.6/1kV Special Explosion Proof Cable

0.6/1kV Special Explosion Proof Cable

Product Introduction

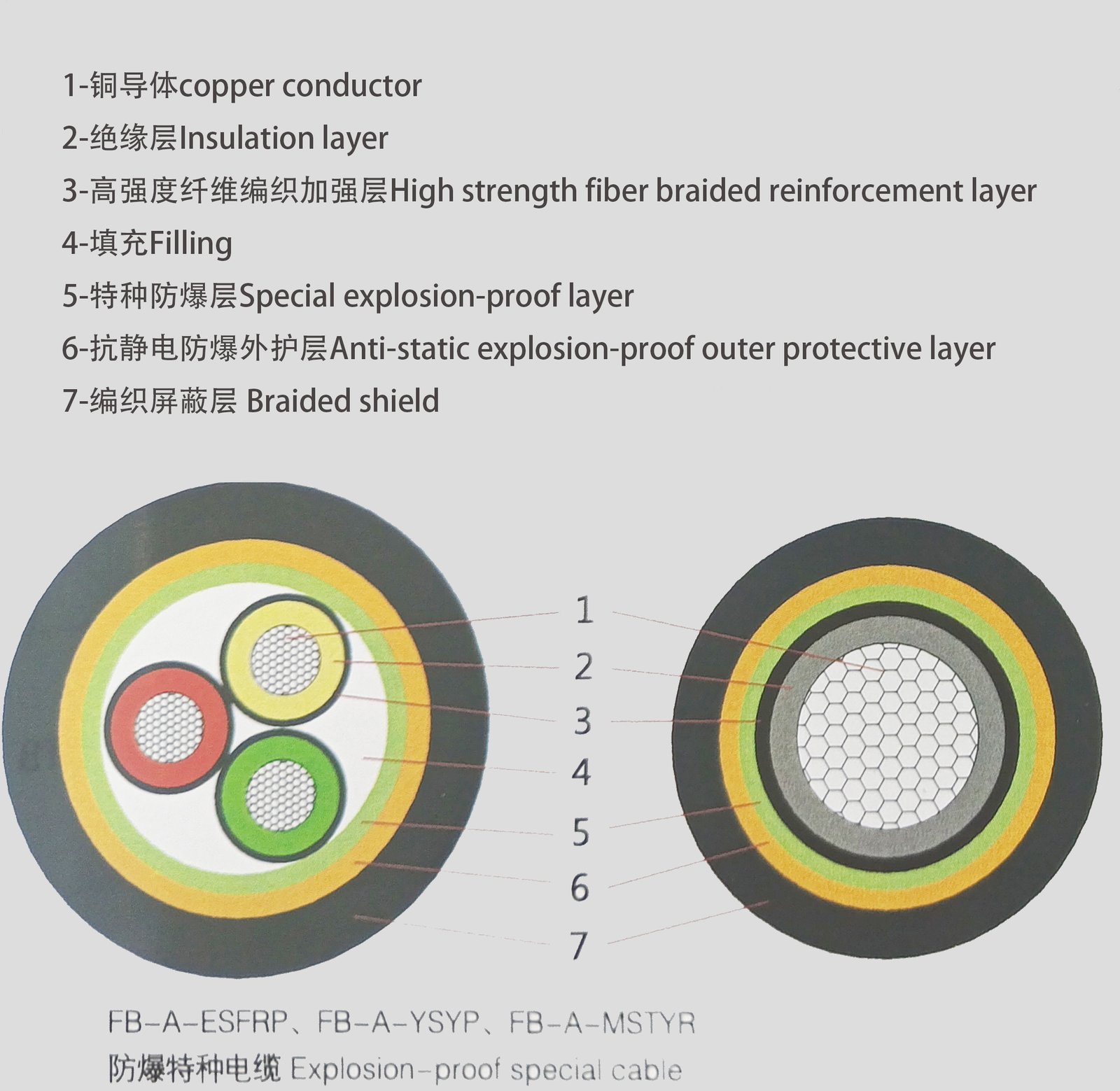

0.6/1 kV special explosion-proof cable is composed of conductor, insulation, high strength braids explosion-proof strengtheninglayer, explosion-proof armored layer and anti-static outer sheath, According to different needs of customers, the insulation layer isdivided into inorganic mineral insulation, rubber insulation and plastic insulation and other types, Under the protection of explosion-proof reinforcement layer and explosion-proof armor, the special explosion-proof cable can withstand the destructive power of 5s kilogram of T’NT at a certain distance. At the same time, the anti-static outer sheath can effectively guide the static electricity generated by thefriction between the cable and non-insulators, and prevent the safety accidents such as fre and explosion caused by static electricity ofmilitary facilities, which perfectly solves the technical problem of easy detonation of”cable electrostatic beam”. Special explosion-proofcable also solves the security problem of explosion-proof system or unit power transmission of current defense combat facilities, such asammunition depot, hangar, military port, storage depot, military and civil airports, tunnels, military exercise bases, large electric powerchemical industry, coal mine, subway terminal and other electrical equipment and facilities. lnorganic mineral insulation explosionproof cable also has: low smoke, halogen free, fame retardant, low toxicity, fire and other combustion characteristics, and through theUK BS6387 the most demanding C, W,2 class and BS8491 fre test, while the cable has good fexibility, strong compression abilitymanufacturing length and other characteristics.

Executive standard

GB 3936.1-2010 “Explosive atmospheres-Part 1: General requirements for equipment”, Q/WHY112-2020 “Rated voltage 0.6/1 kv and below explosion-proof cable”.

Scope of application

Ammunition depot, hangar, military port, storage depot, military and civilian airport, tunnel, military exercise base equipacscircuit, computer room control circuit, trunk, trunk distribution system circuit, dual power control cireuit.Oil platform: power transmission, potentially dangerous explosion area line.Airport terminal: emergency lighting, fire monitoring system, fire alarm system, emergency elevator, fire telephone, emergencypower supply, etc.

Military port: power transmission line in generator room, fire monitoring system, fre alarm system, fue gas emision and ventilatiorline, kitchen power line, large power line, double power control line, emergency lighting, emergency broadcast line, computer room

control line.Chemical industry: power transmission, general lighting, emergency lighting, potentially dangerous explosion lines and other placesMetro tunnel: power transmission, general lighting, emergency lighting, fire monitoring system, fre electrical lines, fue gas

emission and ventilation lineslron and steel metallurgy: power and control system in high temperature environment, emergency power supply, large power line.power supply line that cannot be cut of, transmission line in generator room.Power plant: power line, general lighting, emergency lighting, fire alarm, fire clectrical line.A erospace: power transmission, general lighting, emergency lighting, computer room control lines, large power lines, hightemperature environment power and control lines, potentially dangerous explosion area lines.Department store: power transmission, general lighting, emergency lighting, emergency broadcasting, emergency elevator andlifting equipment lines.

Library, museum, data processing center fire alarm control circuit, fire electrical circuit.Nuclear power plant: power transmission, general lighting, emergency lighting, computer room control line, large power line, hightemperature environment power and control system, potenfially dangerous explosion area line.Places of interest: power transmission, general lighting, emergency lighting, fire alarm, fire protection electrical lines.

Use the feature

Explosion-proof

Under the protection of the strengthening layer, the special explosion-proof cable can withstand the destructive power of 55 kg TNT a certain distance. The anti-static outer sheath can effectively guide the static electricity generated by friction between cables and noninsulators, and prevent the safety accidents such as fre disaster and explosion of military facilities caused by static electricity.

Fire

With inorganic mineral insulation, the cable can be used normally for 180 minutes under 830’℃ fame. Therefore, it is the fireprotection system and safety requirements ofthe use of fire cable products.

Low smoke, halogen free

Non-toxic When the low smoke halogen free fame retardant polyolefins antistatic jacket is used, the cable combustion will notproduce smoke, halogen and toxic gases in case of fire.

Radiation resistant, electromagnetie interference

The resistance value of the insulating material will not change afer radiation. It is an ideal wiring cable in nuclear facilities. Atthe same time, the copper sheath of the cable forms a natural and optimal shielding layer, which can be used in computer room, powerdispatch and control room and other places that need shielding.

High mechanical strength

First of all, the special material determines the high mechanical strength, and secondly, the cable can keep the current surfaceunchanged when it is compressed by extermal force to 2/3 of the original cable diameter.

Type and Description

| Type | Rated Voltage | Description | Cores No.XNominal Cross Section(mm2) |

| FB-A-ESFR | 0.6/1KV | Copper core ETHYLENE – propylene insulated high strength fber braided reinforcedrubber sheath class A explosion-proof flexible cable | 1,2,3,4,5 Cores X 1.5~240 3+1,4+1,3+2 X 2.5~400 |

| FB-A-YSY | 0.6/1KV | Copper core polyolefin insulated high strength fiber braided reinforced polyolefin jacket class A explosion-proof cable | |

| FB-A-ESFRP | 0.6/1KV | Copper core polyolefn insulation high strength fber braided polyolefn outer sheath braided shield class A explosion-proof cable | |

| FB-A-YSYP | 0.6/1KV | Copper core Polyolefin insulation high strength fiber braided polyolefin outer braided shielded class A explosion-proof fexible cable | |

| FB-A-MSTYR | 0.6/1KV | Copper core mineral insulation high strength fiber braided copper sheath polyolefin jacket class A explosion-proof fexible cable |

Fireproof performance

Fire resistance test: Grade C, fire temperature 950 + 40℃, burning 180min;Spray fire test: W class, fire temperature 650℃, frst burning for 15min, then burning and spraying for 15min,Impact fire test: grade Z, fire temperature 950℃, 15min 30 times.

Flame retardant properties

1. Through the GB/T18380 single fame vertical spread test.

2. Through the GB/T18380 provisions of bunching A, B, C class flame retardant test.

3. Low smoke halogen-free cable through GB/T17650 halogen-free test, the combustion gas pHz ≥4.3, conductivity ≤10μs/mm

4. Low smoke halogen free cable through GB/T17650 stipulated smoke densiy test its lieht transmitance is not less than 60%

Electrical characteristics

1.20℃ conductor DC resistance in accordance with GB/T3956-2008 standard:

2.20℃ insulation resistance constant is not less than 3670MΩ ·km;

3. The finished cable should withstand 3.5kV, 5min power frequency voltage test does not breakdown;

4. Outer sheath surface insulation resistance value is less than 1.0 x 109Ω.

Product labeling and application specifications

Product standards

Q/WHY112-2020 Rated voltage 0.6/1kV and below explosion-proof cable

GB3836.1-2010 Explosive atmospheres-Part 1:General requirements for equipment

IEC364-5-523-1999 Electrical installations in buildings -Current carrying capacity of wiring systems

GB/T16895.15-2002 Electrical installations in buildings-Current carrying capacity of wiring systems

Application specification

GB50016-2004 Code for fre protection in building design

DGJ08-93-2002 Code for fire prevention design ofelectric wires and cables in civil buildings

GB50333-2002 Technical code for building clean operation department of hospital

JGJ16-2008 Code for electrical design of civil buildings

GB50067-2014 Code for fire protection design of garages, repair garages and parking lots

GB50217-2007 Specifcation for design ofpower engineering cables

GB/T13029.1-2003 Selection and installation of cables for voltage and power systems of Marine electrical installations

GB50116-2013 Code for design ofautomatic fire alarm system

09D101-6 Layingofmineral insulated cable

Design application selection

In the design and application, it is the same as the ordinary cable, with simple wiring, small space occupancy and more diverselaying methods. The mineral insulated freproof cable does not need to wear pipe, bridge or trough, and can be used with bracket, hanger or open application.

The cable can be laid together with other ordinary cables in the same bridge, cable trench, single-core cable is not allowed to be alone through pipe.

When the route of a certain line is long, and there are parts of the whole line that need to be insulated with mineral fire cables, and there are also parts that can be used with ordinary plastic cables, it can be converted through the conversion box. When plastic cable is available, it can he converted through the converter box.

RELATED PRODUCTS

GET IN TOUCH

We look forward to serving you! Our team will get back to you promptly.